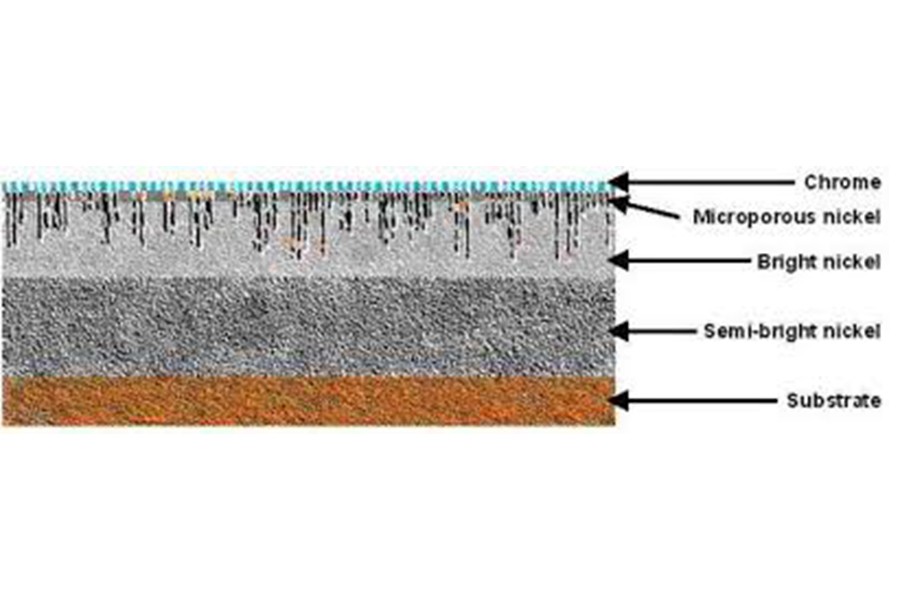

Multilayer Coating Design; The low corrosion resistance of bright nickel + chrome plating duo under harsh service conditions has pushed the coating industry to new searches. The sulfur resulting from the carrier and control agents in the nickel bath was incorporated into the shiny nickel layer formed on the surface. Since sulfur increased the electrochemical activity of nickel, the corrosion resistance of the coating decreased. This situation was first noticed when the salt used as antifreeze on the roads damaged car components. Multilayer coatings were developed to overcome this situation and provide effective corrosion resistance.

According to the research; Nickel plating with copper is technically very attractive in terms of both appearance and corrosion resistance.

Acid copper plating, thanks to its concealer feature, closes micro-scale unwanted pores on the metal surface and eliminates harsh angles. can penetrate geometries containing With its shock absorbing structure, it offers a good undercoating opportunity for nickel + chrome layers.

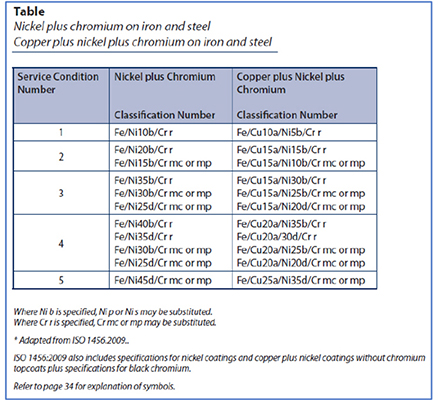

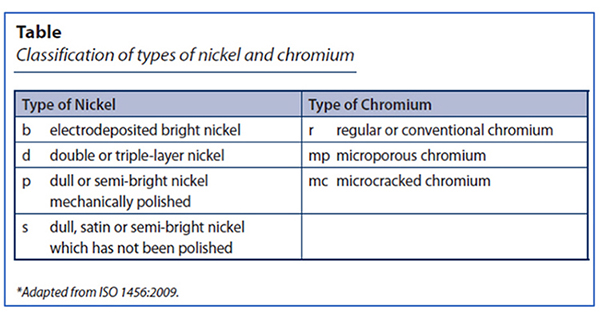

In our facility, with combinations of acidic copper, matte nickel, semi-bright nickel, bright nickel, chrome; We design coatings in accordance with B 456 – 03 standards to meet the corrosion resistance needs of your products under service conditions.