Acid zinc plating is one of the most popular methods used for electroplating purposes.

The main purpose of the zinc plating process is to protect metals from rust or corrosion.

Zinc coatings are also known as altruistic coatings because the zinc coating sacrifices itself to protect the underlying metal from corrosion.

Zinc plating also improves the overall appearance by giving metals a variety of colours, a clean appearance, shine and a pleasant shine.

Zinc coatings have physical properties such as good adhesion and formability, and almost no deterioration of the structural and mechanical properties of the base material during coating.

It comes to the fore with its excellent gloss, high efficiency, low cost and successful results even on hard-to-cover surfaces.

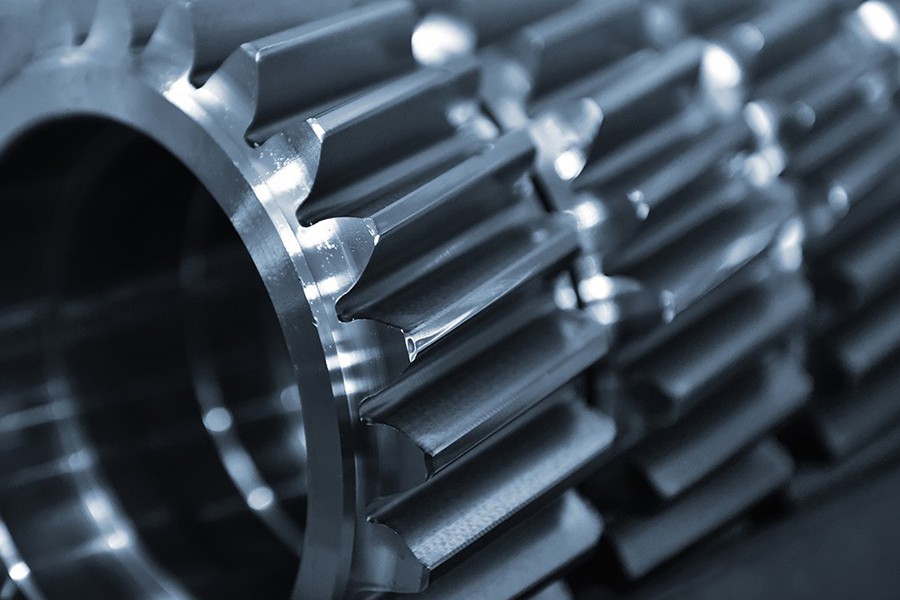

It is mostly used to provide a protective coating to metallic materials in many different industrial areas such as nuts, bolts, fasteners, automotive parts, machinery industry.

The ability of a zinc coating to prevent corrosion varies with the thickness of the coating and the environment in which it is exposed to corrosion.

For this reason, the service conditions in which the product will be used are taken into account when determining the coating thickness to be applied.