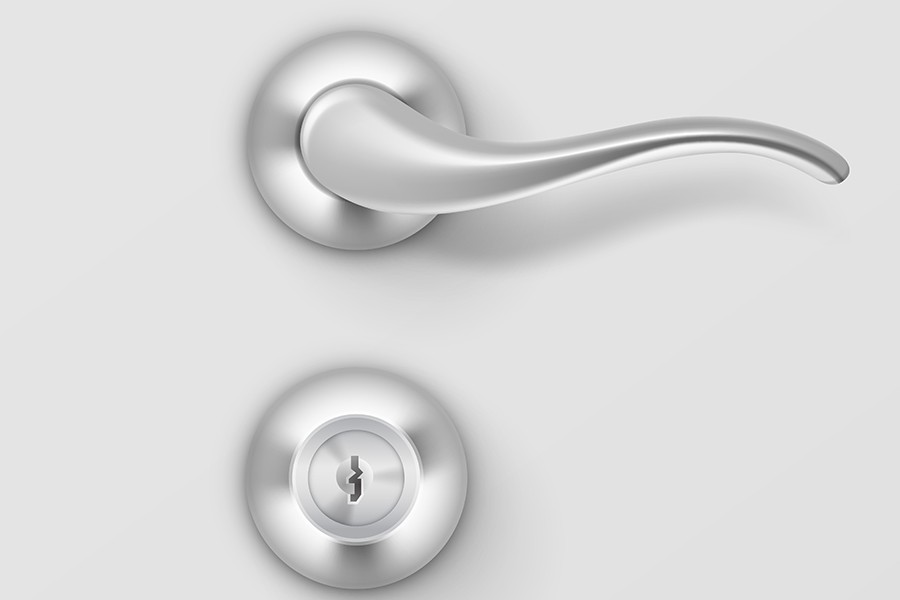

Matte Nickel process is applied as satin or semi-gloss, depending on the additives preferred in the bath content. The matte nickel layer, which does not contain sulfur from carriers, has lower electrochemical reactivity than shiny nickel and thus provides better corrosion resistance. Considering this feature; Matte nickel is used as the substrate of bright nickel for conditions where corrosion resistance is important.

Due to the fact that matt nickel layer is a good primer, it also serves as the substrate in acidic copper plating applications. Matte nickel plating is also preferred in decorative applications or functional engineering applications with its unique aesthetics.