Electroless nickel plating is the catalytic reduction of nickel ions in an aqueous solution.

and subsequent deposition of nickel metal on the surface without the use of electrical energy.

is a process. It is a technique of depositing a layer of nickel-phosphorus alloy on the workpiece (metal or plastic).

Phosphorus ratio in these alloys can vary between 2% and 14%. Metallurgical properties of the coating

depends on the phosphorus ratio.

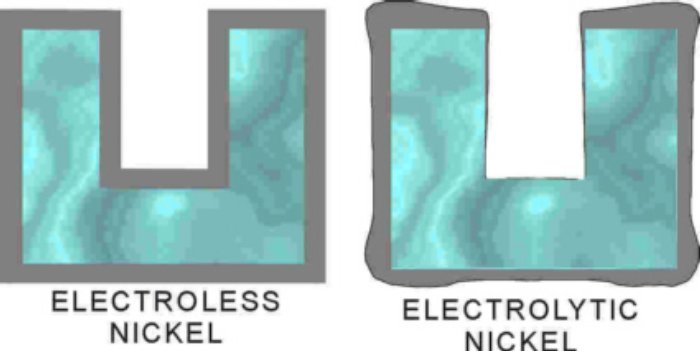

In electroless coatings, the thickness distribution is extremely homogeneous, regardless of the shape and size of the part.

This characteristic feature makes electroless coatings especially deep indentations, holes, interior surfaces, blind holes.

and made it widely used for gear parts. However, as other characteristic features;

effective corrosion resistance, wear resistance, ductility, wettability, solderability,

electrical conductivity and hardness.

Thanks to its exceptional corrosion resistance and high hardness, this process is suitable for heavy-duty environments.

It has a wide usage area in the oil field and maritime sector. Other typical usage areas;

aerospace, automotive, food processing equipment, fluid power components, textile machinery, hydraulics,

plastic molds, electronic components, chemical processing equipment and printed circuit boards.